Futian Aumark S1 Single-row Grid-Type Light Truck

Gold Power Chain, High Efficiency and Low Fuel Consumption

Foton Cummins F2.8 Engine: The world's leading 2.8-liter power unit, featuring a powerful output of 163 horsepower and a peak torque of up to 450 Newton-meters. It has a prominent low-speed high-torque characteristic, making it more powerful for starting, climbing, and overtaking.

Intelligent fuel-saving technology: Utilizing a high-pressure common rail fuel system, the combustion process is more efficient, resulting in a fuel consumption of 1-2 liters lower per 100 kilometers compared to products in the same category. This significantly reduces operating costs.

Wanli Yan 6-speed transmission: The shifting process is smooth and effortless, with precise speed ratios that are perfectly matched to the engine, achieving a perfect balance between power and economy.

Foton Aumark S1 is a high-end intelligent light truck specially designed by Foton Automobile based on European standards, integrating the world's top supply chain resources. It is created for modern urban logistics. The 163-horsepower 4.17-meter single-row cargo grid light truck (BJ5048CCY-FM8) recommended in this advertisement, with its powerful engine, excellent performance, reliable quality and flexible and diverse cargo grid structure, has become a star product in green transportation, agricultural products transfer, and less-than-truckload delivery and other fields. It provides the ultimate solution for every entrepreneur who pursues efficiency.

| Announcement Model: | BJ5048CCY-FM8 |

| Type: | Truck with side walls |

| Drive type: | 4X2 |

| Wheelbase: | 3360mm |

| Box length category: | 4.2 meters |

| Engine: | Foton Cummins F2.5NS6B172 |

| Transmission: | Fastrite 8J45TA |

| Rear axle ratio: | 4.875 |

| Overall vehicle length: | 5.995 meters |

| Overall vehicle width: | 2.2 meters |

| Overall vehicle height: | 3.16 meters |

| Front wheel track: | 1725mm |

| Rear wheel track: | 1590mm |

| Overall vehicle weight: | 2.72 tons |

| Rated load capacity: | 1.58 tons |

| Total mass: | 4.495 tons |

| Maximum speed: | 105km/h |

| Place of origin: | Changping, Beijing |

| Tonnage class: | Light truck |

| Approach angle: | 20 degrees (°) |

| Departure angle: | 16 degrees (°) |

| Front/rear suspension: | 1.11/1.525 meters |

| Energy type: | Diesel fuel |

Core advantages and features of the product

Reliability and Comfort of Super Trucks

Extremely long maintenance period: The engine supports a 40,000-kilometer extremely long maintenance interval, reducing the number of visits to the repair station and the time spent there, and improving the operational efficiency.

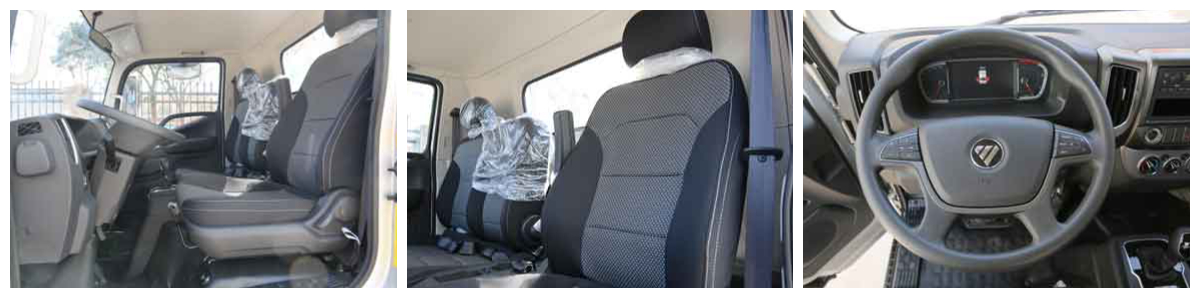

Ergonomically designed cab: Standard equipped with airbag shock-absorbing seats, with ample space and a reasonable layout. The interior design is car-like, featuring a multi-function steering wheel, electric windows, air conditioning and other configurations, effectively alleviating driving fatigue.

Outstanding noise reduction: Excellent NVH (Noise, Vibration and Harshness) sound insulation and noise reduction engineering, significantly reducing the noise inside the vehicle, creating a quiet driving environment.

Warehouse-style containers, versatile and flexible

Fully transparent on all sides, easy to load and unload: The warehouse gates can be opened on three sides or all sides, facilitating loading and unloading of goods by forklifts and manual labor from multiple angles, significantly enhancing operational efficiency.

Ventilation and sun protection, wide applicability: The grid structure not only ensures good ventilation to prevent goods from getting damp but also can be equipped with a tarpaulin to achieve sun protection and rainproofing, meeting various transportation needs for goods.

Sturdy and reliable, safe load-bearing: The solid frame and reliable locking mechanism ensure the stability and safety of goods during transportation.

Intelligent safety, full protection throughout

Active safety: Standard equipped with ABS anti-lock braking system, optional ESP electronic stability program, ensuring the vehicle remains stable in emergency situations. Air brake system, with quick response and strong braking force.

Passive safety: The high-strength steel cab complies with European safety regulations. In the event of a collision, it can effectively absorb energy to ensure the safety of passengers and drivers.

| Engine parameters | |

| Engine brand: | Futong Cummins |

| Engine model: | Futong Cummins F2.5NS6B172 |

| Engine information: | Fukang F2.5 |

| Number of cylinders: | 4 cylinders |

| Fuel type: | Diesel fuel |

| Cylinder arrangement: | Straight-line |

| Displacement: | 2.498L |

| Emission standards: | National VI |

| Maximum output power: | 120kW |

| Maximum horsepower: | 163 horsepower |

| Maximum torque: | 460N·m |

| Maximum torque speed: | 1500-1800rpm |

| Rated speed: | 2900rpm |

| Transmission parameters | |

| Transmission model: | Faist 8J45TA |

| Transmission brand: | Faist |

| Shifting method: | Manual |

| Forward gears: | 8th gear |

| Reverse gears: | 2 |

MATERIALS AND CRAFTSMANSHIP

1. Cab and Body:

Materials: The cab and body are made of high-strength steel frames, combined with high-quality galvanized steel plates. They have excellent resilience against denting and corrosion resistance, ensuring that the body remains as new for ten years. The front panel components are made of PP/ABS engineering plastics, which have good toughness and are unlikely to crack even under minor collisions.

Process:

Cathodic Electrocoating: The entire cab of the vehicle undergoes the vehicle-wide cathodic electrocoating process, achieving seamless rust prevention treatment. Its salt spray resistance exceeds industry standards, effectively coping with harsh environments such as humidity and acid rain.

Robotic Precise Welding: Key parts are welded using robotic automation, ensuring uniform and secure weld points, high structural strength, and enhanced safety and durability.

2. Chassis and Frame:

Material: The frame is made of 510L high-strength steel, which has high yield strength, strong load-bearing capacity and is lighter in weight, providing a guarantee for compliant multi-load operations.

Process:

Rolling forming technology: The longitudinal beams of the frame are formed by rolling a single piece of high-strength steel plate, resulting in a more complete structure and more uniform force distribution.

Spray coating process: The core components of the chassis are treated with an anti-corrosion process of epoxy primer + spray coating. This process has strong adhesion, is resistant to wear and impact from stones, and has a longer service life.

Pallet box:

Material:

Frame: Made of high-strength rectangular steel tubes, it is sturdy and durable.

Fence: High-quality carbon steel, with anti-rust treatment applied to the surface.

Base plate: Anti-slip patterned steel plate, with strong load-bearing capacity, and resistant to wear and slip.

Process:

CO2 gas shielded welding: Ensure that the welding area is firm and aesthetically pleasing, with no incomplete or missed welds.

Overall hot-dip galvanizing / powder coating treatment: (Optional process) Provides stronger rust prevention capabilities, especially suitable for transporting corrosive goods or operating in humid areas for an extended period.

| Trunk parameters | |

| Box form: | Garage-style |

| Box length: | 4.17 meters |

| Box width: | 2.1 meters |

| Internal width of the container: | 2.1 |

| Cab parameters | |

| Cab width: | 2060mm |

| Passenger capacity: | 3 people |

| Number of seats: | Single row |

| Fuel tank | |

| Tank capacity: | 120L |

| Chassis parameters | |

| Front axle allowable load: | 1575kg |

| Description of rear axle: | 6T |

| Rear axle allowable load: | 2920kg |

| Ratio: | 4.875 |

| Number of spring plates: | 3/8+6 |

CORE APPLICATION SCENARIOS

This OMC S1 4.17-meter storage fence vehicle is an ideal choice for the following fields:

Green Pass Transportation / Agricultural Products: Transporting vegetables, fruits, live poultry, etc. The warehouse structure has ventilation and air circulation, which can effectively ensure the freshness of the goods and reduce losses.

Less-than-truckload (LTL) express delivery and logistics distribution: Suitable for the transfer of LTL goods between urban and rural areas. It offers flexible loading and unloading capabilities and can quickly meet the distribution demands of various categories and multiple batches.

Construction materials and household supplies transportation: Transporting irregular goods such as pipes, plates, and hardware. The warehouse fence structure is convenient for bundling and fixation.

Waste recycling and resource regeneration: For transporting lightweight items such as waste paper and plastic bottles, the open structure makes it easy to load and compress.

Mobile sales and mobile warehouses: They can be modified into mobile fruit trucks, clothing sales vehicles, etc. The open design on all four sides makes it convenient for displaying goods.